Before anything can be produced it must be imagined.

In packaging industry before packaging material can be produced, content must be analyzed.

Olpo group Sp. z o.o. dedicates all efforts to explore variety of options as a tool to offer the best possible packaging solutions to its customers.

Please meet our offer below and in case of any additional questions or requests please do not hesitate to contact our sales team.

OFFER MENU

Roll form for automatic packaging

Single layer (monolayer) films

Polyethylene: LLDPE, LDPE.

LDPE (low density polyethylene) and LLDPE (linear low density polyethylene) are being produced by extrusion of melted mass to expand the film. It is used as sealing layer in different laminates as well as separate packaging material. Polyethylene can be completely recycled and used repeatedly. LLDPE possess more puncture resistance comparing to LDPE.

Our LDPE film can be used in direct contact with food products. Usually products that do not require high barrierity can be packed in this film. We can supply polyethylene film in thicknesses from 24 to 170 microns with HD Flexo print applied. Upon the customer's request we can supply receive colored film, which is extruded with a color component. Our LDPE film can be used in direct contact with food products. Usually products that do not require high barrierity can be packed in this film.

Our films are characterized by high flexibility and strength. They are successfully run on HFFS (horizontal form-fill-seal) and VFFS (vertical form-fill-seal) machines. The advantage of these films are possibility of welding both A to A, and A to B sides.

The most popular choice for :

- - frozen food (frozen fish, berries, vegetables)

- - milk packaging (black&white film)

- - bakery articles (breads, bagels, pitas, tortillas)

- - hygienic articles (toilet paper, personal care)

- - household

- - garden soil

Besides monolayer films for packaging we also advise using laminates, consisting of different films, as BOPP, PET, LLDPE, also metalized.

If you have any additional questions, please do not hesitate to contact us.

Polypropylene: CPP, OPP, BOPP

Polypropylene is the world's second-most widely produced synthetic plastic, after polyethylene. BOPP is widely used as a packaging material for packaging products such as snack foods, fresh produce and confectionery. Polypropylene is recyclable and has the number "5" as its resin identification code.

Polypropylene films are characterized by high clarity, good optics and rigidness. Biaxial orientation (BOPP) increases strength and clarity of film. Ability to use 20 microns film and to keep required rigidness increases the output of this film.

Usually used to pack:

- - ice creams

- - pasta

- - chocolate

- - chips and snacks

- - confectionary products

- - tea

- - disposable goods

Olpo group Sp. z o.o. supplies CPP, OPP and BOPP films with print up to 10 colors in Flexo HD. Pearl and metalized films can be delivered upon the request.

Above films are perfectly run on Horizontal Form Fill Seal (HFFS) machines as well as Vertical Form Fill Seal (VFFS) machines:

If you have any additional questions, please do not hesitate to contact us.

Laminates for general purposes

Lamination is a process which combines two or more films into a sandwich structure. A laminating machine covers one layer of film with adhesive coating before pressing it to a second layer. We are using a solvent-free lamination.

Laminates increase puncture resistance, overall strength of packing material and barrier properties. High-quality raw materials by reputable suppliers guarantee our laminates to have unique optics and high hot tack force. Tack force is very important indicator when it comes to Vertical Form Fill and Seal packaging (VFFS), as running film should be strong enough to hold the content that falls from some height without tearing. The filling method is basically to fill the product into the package from a certain height which would cause strong impact to the bottom of the package. If the bottom of package cannot withstand the impact, it would break so there is a package breakage.

Every laminate can be printed up to 10 colors using Flexo HD technique with inside printing. The surface can be either glossy or matt. We suggest 3-layered laminates (triplex) for more demanding products.

Our company also supplies laminates with polyethylene as a sealing layer with BOPP, CPP, BOPET, and BOPET met. Our technology allows applying different coatings, namely easy-peel, anti-fog, open-close and UV blocker, matt and gloss finishes.

Usually used to pack:

| Laminates with sealing layer - polyethylene |

|

|

| Laminates with sealing layer - polypropylene |

|

|

Above laminates are perfectly run on Horizontal Form Fill Seal (HFFS) machines as well as Vertical

Form Fill Seal (VFFS) machines:

If you have any additional questions, please do not hesitate to contact us.

Medium barrier PA/PE films

Olpo group Sp. z o.o. specializes in supplying 9-layer medium barrier films. Our films includes PA component in outer layer that allows achieving medium barrierity to O2. These films can be successfully used both in vacuum packaging and in modified atmosphere packaging (MAP). Available as medium barrier (PA/PE) or high barrier (PA/EVOH/PE).

Also available with EVOH barrier layer, easy peel, open-close and antifog applications.

Modified atmosphere packaging (MAP) is a technology of internal package atmosphere modification in order to improve shelf life. Modified atmosphere packaging products are ideal for preserving fresh and processed meats, ready-made meals, seafood, cheese, fruits and vegetables. Olpo group Sp. z o.o. proudly offers MAP films to help prevent food spoilage, inhibit oxidation and ensure products reach the end consumer in the best possible condition.

In our offer we also have premade PA/PE pouches for vacuum packaging.

Medium barrier PA/PE films supplied by Olpo Group Sp. z o.o. have next advantages:

- - Possess effective barrier against gases, steam (moisture) and UV rays

- - Highly resistant to puncture

- - Extremely transparent and glossy

- - Perfect forming qualities

These films are usually used to pack:

- - Cottage cheese

- - Meat

- - Ham and other cold meat products

- - Cheese

- - Fresh fish and seafood

- - Ready meals

Medium barrier films supplied by Olpo group Sp. z o.o. are successfully run on tray sealers as well as thermoforming machines. PA/PE 9-layer films can be applied as both top/lidding film and bottom/forming film.

If you have any additional questions, please do not hesitate to contact us.

High and medium barrier laminates

Olpo group Sp. z o.o. is successfully supplying different markets with high- and medium barrier laminates. Laminates have increased barrier properties to gases (O2), water and UV rays. They are perfectly sealable to PE, PP, APET, PS, PVC.

Structure of the laminate is determined upon the product shelf life, method of packaging and storing conditions. Usually these laminates have two- and three-layers structures. The most popular medium barrier laminates structures is PA//LDPE as well as BOPET//PE/EVOH/PE. The highest barrier properties can be achieved including Al (aluminum) layer to the laminate structure, which are usually used for packing among others infant formula. We are able to supply printed laminates with 10 colors Flexo HD technique.

Barrier layer including in its structure EVOH (ethylene vinyl alcohol) has strong barrierity against oxygen and gas. It minimizes the gas motion between inner and outer atmosphere of package, whereby extends the shelf life of food products and protect their nutrients against bacteria.

High barrier laminates are usually used in modified atmosphere packing (MAP) as well as in vacuum packaging.

Olpo group Sp. z o.o. supplies high barrier laminates as top web film with an options of : easy peel, anti- fog, open-close and UV blocker.

Usually used to pack:

- - raw meat

- - fresh meat products

- - poultry

- - fresh fish and seafood

- - cottage and other cheese

- - dairy products

- - ready meals

- - pet food

These laminates are successfully run on

- - flow pack machines. Specially designed films for high speed packaging machines with excellent strength and sealing properties at initially low temperatures. To keep high pace of the machine to the recipe of film is added antistatic elements that can adjust friction, whereby machine does not block the film.

- - thermoforming machines. Our films for thermoforming possess perfect forming qualities, high puncture resistance and high resistance to oils and acids. Specially designed PE sealing layer perfectly seals fatty areas. We strongly advise to use our bottom (forming) film along with our top-web film.

- - tray sealers. Trays (e.g. APET) are filled with product and sealed with a top web film. Our films have a superior abrasion and perfect sealing properties, that can keep high pace of the machine.

If you have any additional questions, please do not hesitate to contact us.

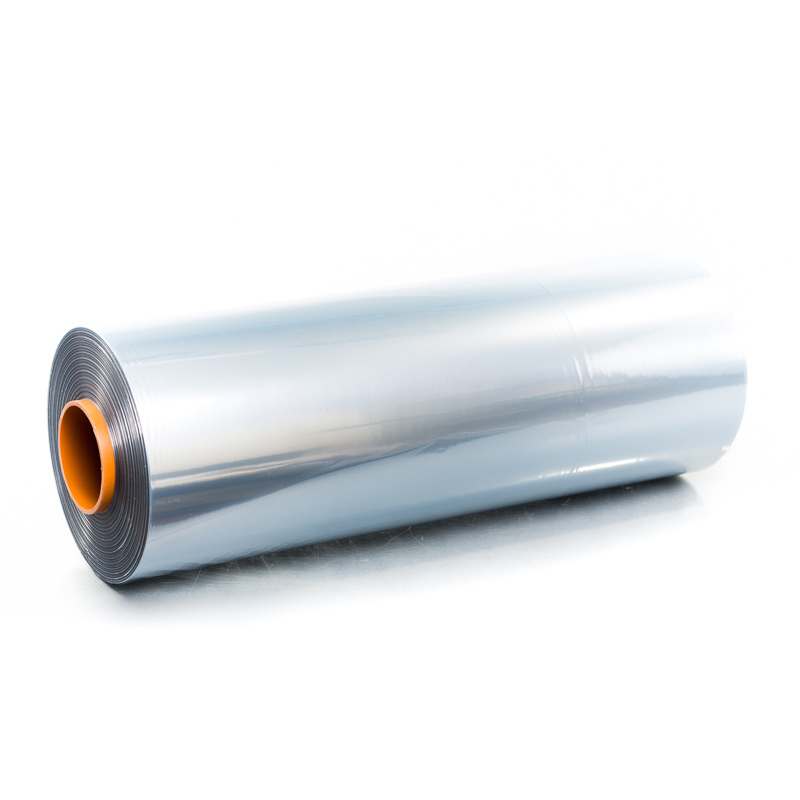

Shrink film

Shrink film is a material made up of polymer plastic film, which has good optical, mechanical and shrinking properties. When heat is applied, the film shrinks tightly over whatever it is covering. Heat can be applied with a handheld heat gun, or the product and film can pass through a heat tunnel on a conveyor. This film is usually applied in beverage industry to hold multiple items or smaller packages of cans, bottles, as well as packages of sugar, salt, flour etc.

We can supply both printed Flexo HD up to 10 colors and unprinted shrink films. Unprinted films can be transparent or colored films upon the customer's request. Thanks to reputable supplier of raw materials our films has superior optics and mechanical properties. Our specialists are able to adjust required film to the machine of the customer to achieve high transparency, gloss and advanced shrink properties, wherein avoiding wrinkles on final product appearance.

Usually these films are used to pack:

- - beverages in bottles

- - beverages in cans into 6- or 12- packs

- - bulk food products

- - industrial products

- - household products

Ou films are successfully run on Shrink Side- Sealers, Shrink Sleeve-Wrappers and Shrink Tunnels providing strength and stability of the pack, high transparency and no burning in the heating tunnel.

If you have any additional questions, please do not hesitate to contact us.

Premade pouch

3 side seal pouch

Three side seal pouches is a simple and very convenient form of packaging that can be used to pack almost any product. The pouch has 3 welds/seals (the reason why it is usually called like that is obvious) and 1 open side (usually top or bottom) for content filling. After product is inside the pouch is sealed using a heat sealer. Pouches are delivered in cartons 500pcs or 1000pcs per carton upon customer's request.

Olpo group Sp. z o.o. offers both printed using Flexo HD technique up to 10 colors and unprinted pouches. This format of packaging is suitable for 50g up to 25kg weights with many options. Three side sealed pouches can be used for packing a wide range of products, like:

- - Frozen fish

- - Pet foods

- - Cosmetics

- - Coffee and tea

- - Organic products

- - Sugar

- - Cheese

- - Frozen products, etc.

Three side seal pouches can be produced using both monolayer film as and 2-, 3-layers laminates. The film structure is determined after analyzing the product requirements, as shelf life, storing conditions etc. After all we can use different plastics: LLDPE, BOPET, BOPP, MET-PET, Al etc.

Upon the customer request three side sealed pouches can obtain:

- - Euro hole/ euro slot

- - Re-sealable ZIP lock

- - Tear notch / V-notch

- - Degassing valves

- - Transparent window

- - Matt and gloss finishes

- - Easy tear/ Laser score

- - Metalized coating for higher barrierity

If you have any additional questions, please do not hesitate to contact us.

Stand-up pouch/ Doy pack

A Doypack or stand-up pouch is a sealed plastic bag that is designed to stand upright. Doy pack is a convenient solution of product presentation, basically on the store shelves. Thanks to the technology of sealing the bag can stand stable on the surface displaying the product in an upright position. They can be aseptically filled or filled on normal packaging lines.

These packagings are used for both manual and automated packaging of foodstuff:

- - Coffee

- - Tea

- - Spices

- - Dried fruit

- - Nuts

- - Juice

- - Mayonnaise

- - Candy

- - Seeds

- - Chemicals (i.e. liquid soap)

- - Tobacco, etc.

Three side seal pouches can be produced using laminates for general purposes or medium and high barrier lamiantes. The film structure is determined after analyzing the product requirements, as shelf life, storing conditions etc. After all we can use different plastics: LLDPE, BOPET, BOPP, MET-PET, Al etc.

Upon the customer request stand-up pouch can obtain:

- - Euro hole/ euro slot

- - Matt and gloss finishes

- - Re-sealable ZIP lock

- - Tear notch / V-notch

- - Degassing valves

- - Transparent window

- - Easy tear/ Laser score

- - Metalized coating for higher barrierity

- - Venting system

- - Handle hole

If you have any additional questions, please do not hesitate to contact us.

PA/PE vacuum bags

Vacuum bags are suited to a wide range of perishable products. These pouches will surely provide extended shelf-life and protection for storage and transportation of your product. Material structure is specially determined upon the requirements of the content. Usually we supply vacuum bags with medium barrier 9 layered PA/PE film. These films includes PA component in outer layer that allows achieving medium barrierity to O2.

Olpo group Sp. z o.o. delivers bags for vacuum packaging as well as for modified atmosphere packing (MAP) in the form of 3 - side seal bags. Offered vacuum bags may have next options:

- - Euro hole/ euro slot

- - Flexo HD print up to 10 colors

- - Matt and gloss finishes

- - Transparent or colored

- - Medium barrier (PA/PE) or high barrier (PA/EVOH/PE)

- - Possess effective barrier against gases, steam (moisture) and UV rays

- - Highly resistant to puncture

- - Extremely transparent and glossy

- - Perfect sealing properties

- - No film folding

These bags are usually used to pack:

- - Fresh and processed meat

- - Poultry

- - Cheese

- - Fresh fish and seafood

- - Dry nuts

- - Olives, etc.

If you have any additional questions, please do not hesitate to contact us.

Flat bottom pouch/ Stabilo/ Quad seal

Pouch with four sealed sides usually are called flat bottom pouch or stabilo pack or quad seal bag. Flat bottom pouch has a side gusset and four main sides which extend place for product branding. They are perfect for palletisation in terms of quad form of the pouch. Usually made from laminates as well as co- extruded films.

Stabilo pack is considered to be one of the most stylish formats of packaging. It is called stabilo because of its quad bottom that guarantees stable and reliable position. Sealing of each side increases strength of the bag. It is usually used to pack coffee and other products.

This format is suitable for 350g to 20kg weights. Olpo group Sp. z o.o. offers different options:

- - Flexo HD print up to 10 colors

- - Euro hole/ euro slot

- - Matt and gloss finishes

- - Perfect strength

- - Medium and high barrier

- - Venting system on the side gusset

- - Re-sealable ZIP lock

- - Tear notch / V-notch

- - Degassing valves

- - Transparent window

- - Easy tear / Laser score

These bags are usually used to pack:

- - Coffee

- - Fertilizer

- - Cheese

- - Protein powder

- - Tea

If you have any additional questions, please do not hesitate to contact us.

Wicket bags (bakery)

Wicket bags are produced using PE or CPP; pouches are supplied on a wire, generally in groupings 100 to 250 bags and used by high speed packaging machine to pack bread, vegetables, fruits and frozen meat. It is easy to use and efficient in Automatic, Semi- automatic and Manual load applications. Popular thickness is from 24 microns to 40 microns.

The bags are closed by heat sealing, crimped with a C-Ring, tied or taped shut.

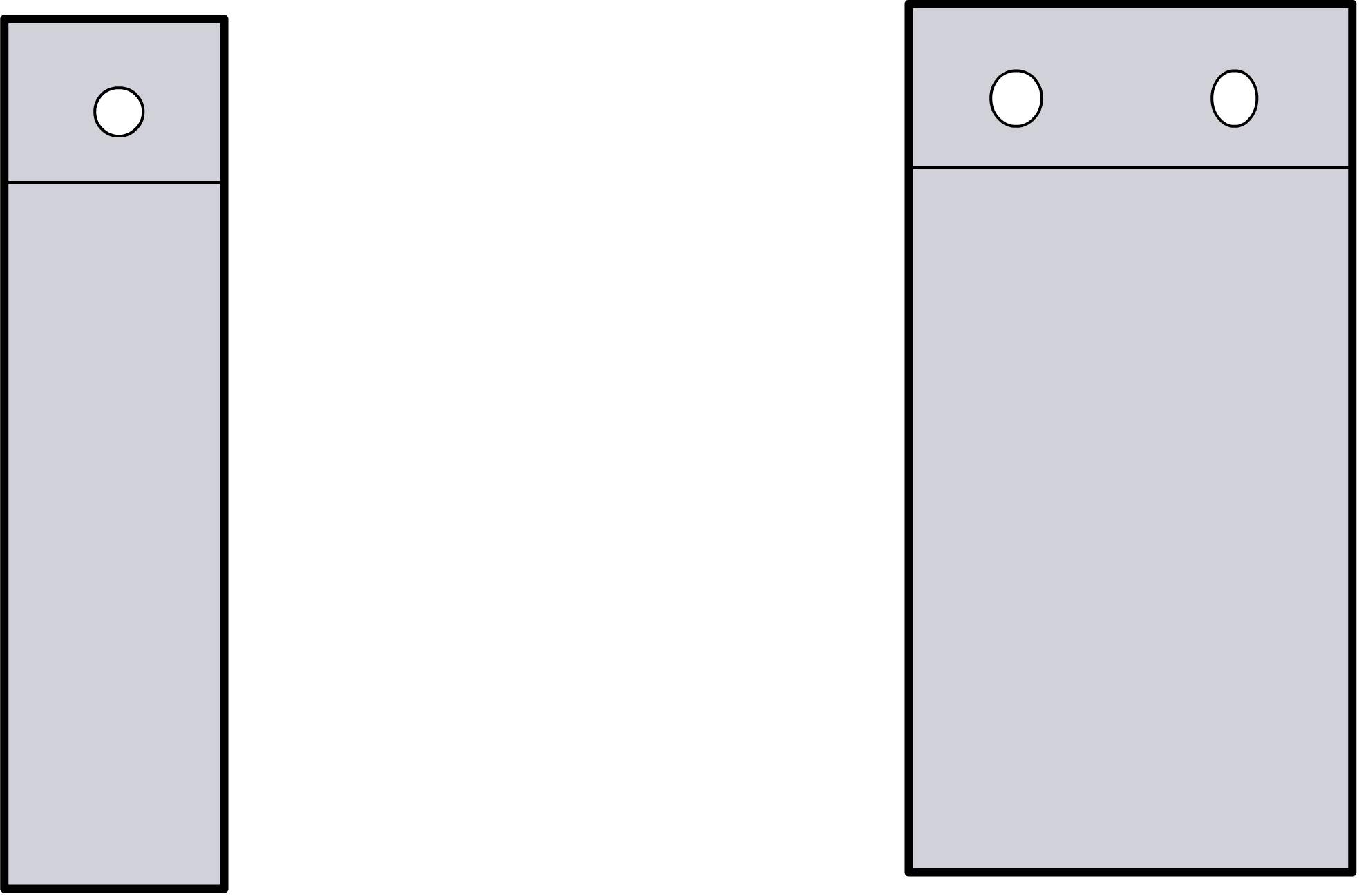

We can deliver one or two wicket holes bags (with or without a clap):

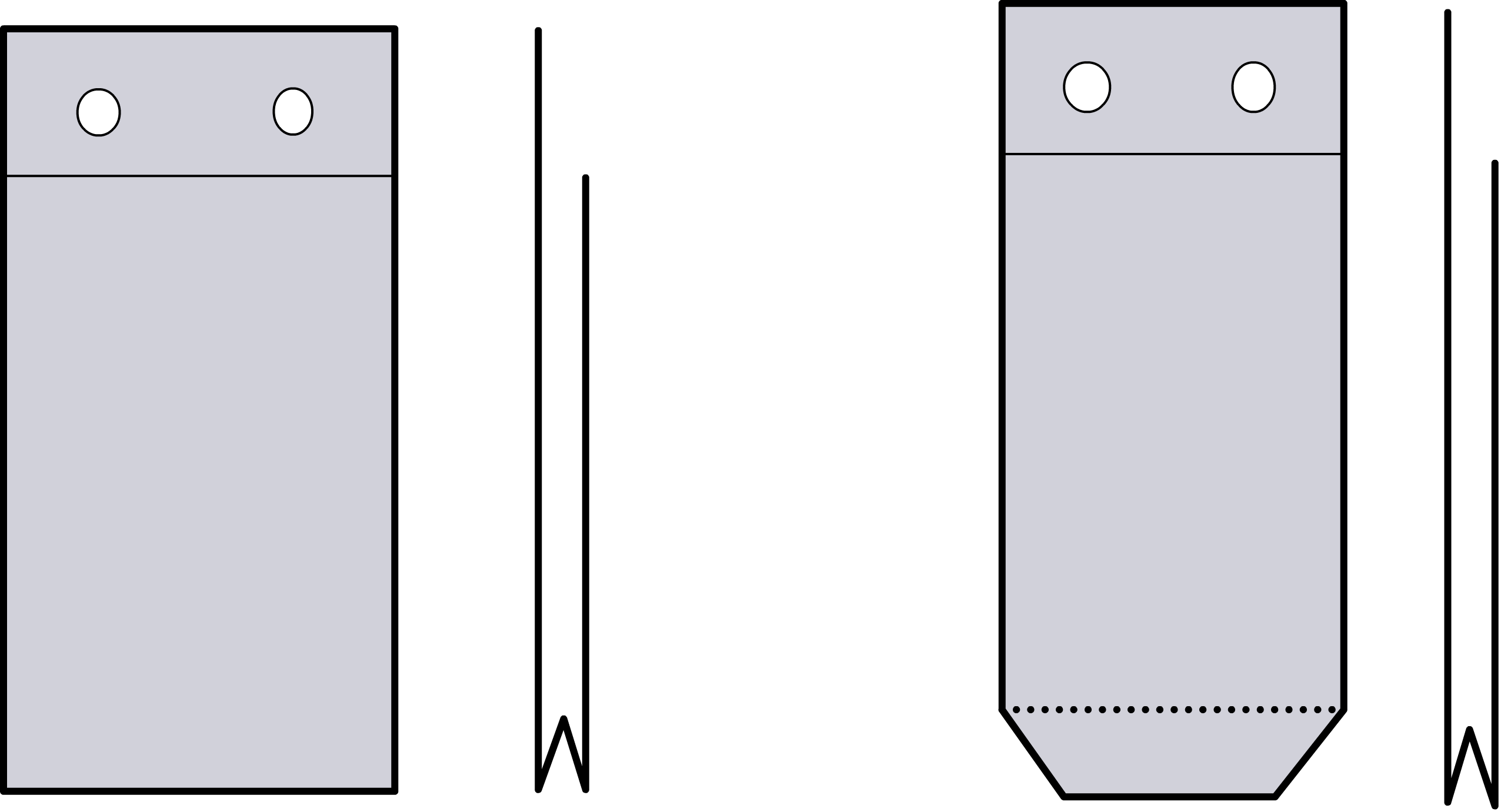

The bags with a bottom gusset can be produced in 2 options: rectangular or trapezoidal.

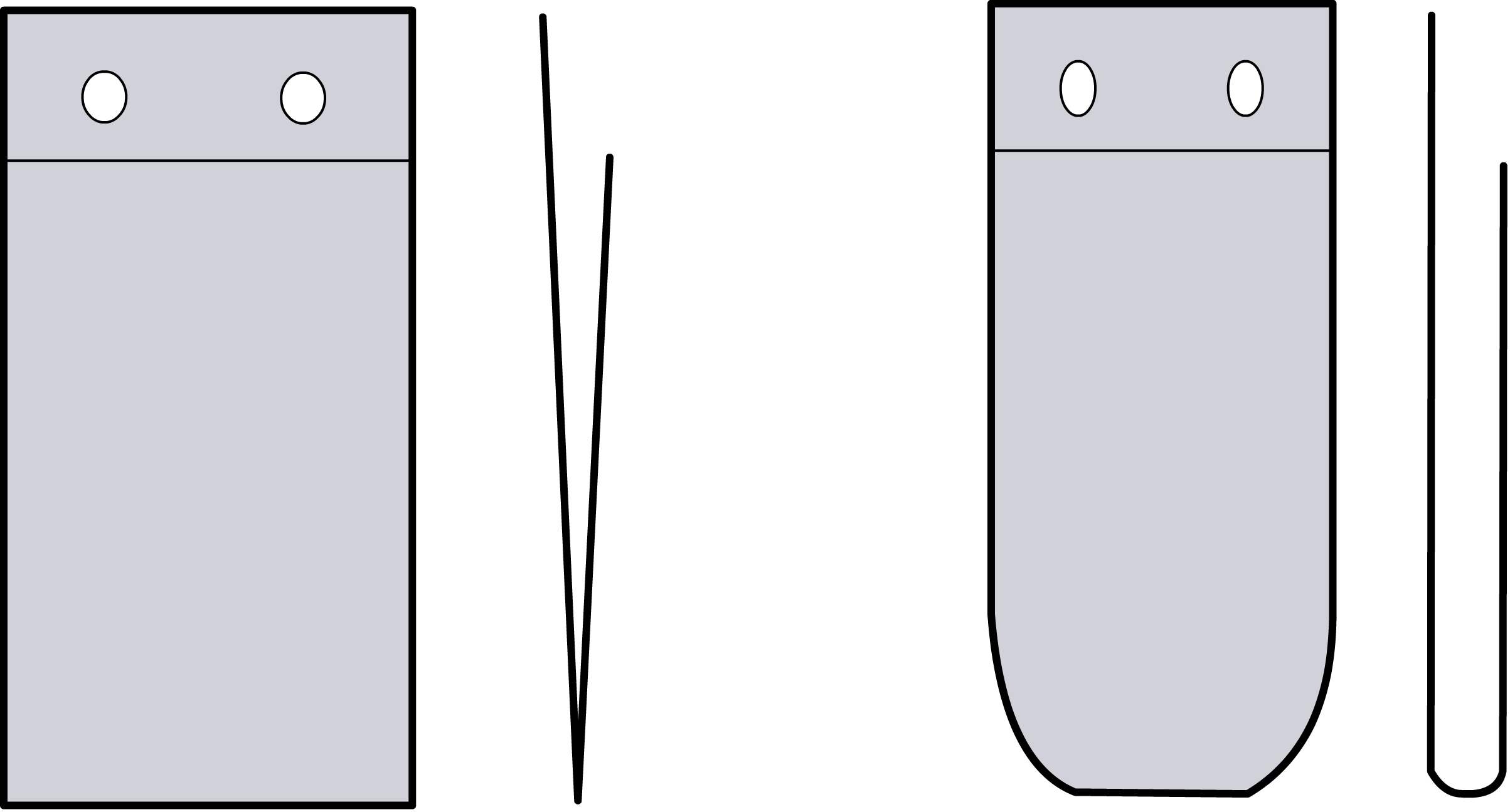

The bags with no bottom gusset can be produced in 2 options: rectangular bottom or oval bottom.

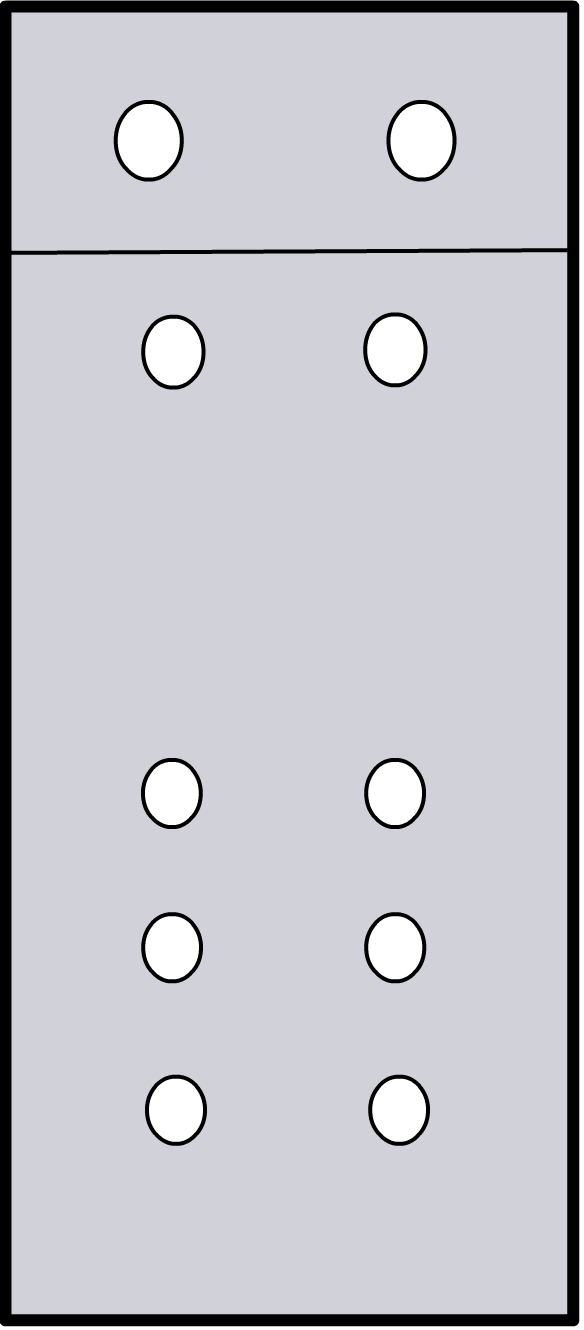

Additionally the bags can obtain up to 8 holes with 5mm in diameter.

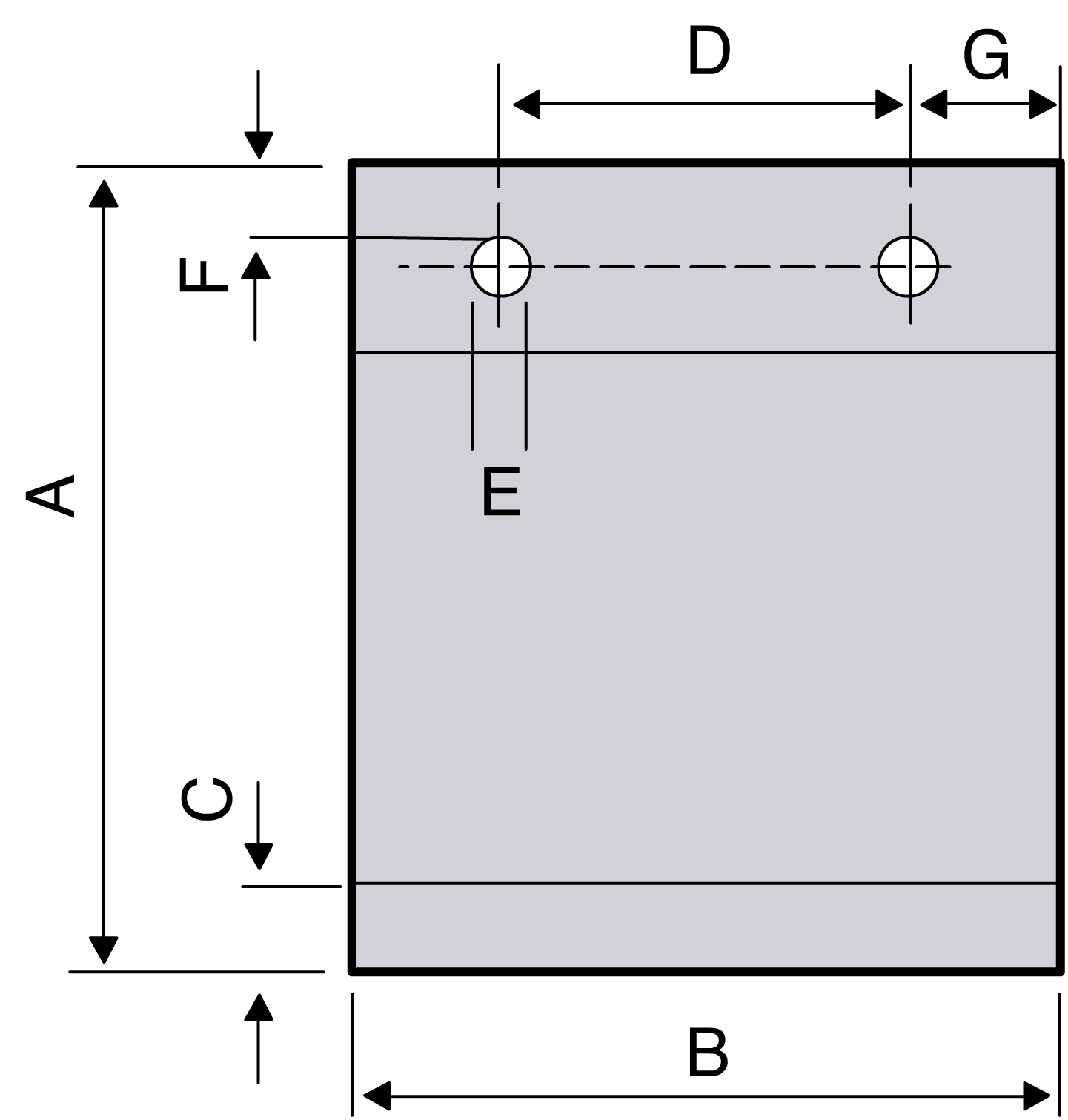

Below you can find a possible dimension of supplied wicket bags:

| Dimensions | Value |

| A- Bag height without a clap | 150-710mm |

| B- Bag widthap | 110-390mm |

| C- Bottom gusset | 20-110mm |

| D- Distance between holes | max. 260mm |

| E- Holes diameter | 14mm |

| F- Height of the holes position | min. 10mm |

| G- Width of the holes position | min. 40mm |

Olpo group Sp. z o.o. supplies wicket bags which below options:

- - Good sealing properties

- - High glosst

- - Flexo HD print to 10 colors

- - Transparent or colored

- - With or without wicket holes

- - Bottom gusset

- - Flat bottom

- - Additional holes

If you have any additional questions, please do not hesitate to contact us.

Other

Carrier bags

Carrier bag was initially designed for carrying customer's purchases. Later on this bag was examined in terms of advertising. Printing own logo on the bag allows to make silent advertising, while a customer carriers the purchase in the bag to target place it reaches other people attention. Frankly speaking, printed carrier bags enhance brand identity among society at comparably low cost.

Olpo group Sp. z o.o. offers carrier bags produced from LDPE, MDPE and HDPE films with different thicknesses upon the customer's requirement. It can be transparent, colored or printed using Flexo HD technique up to 10 colors.

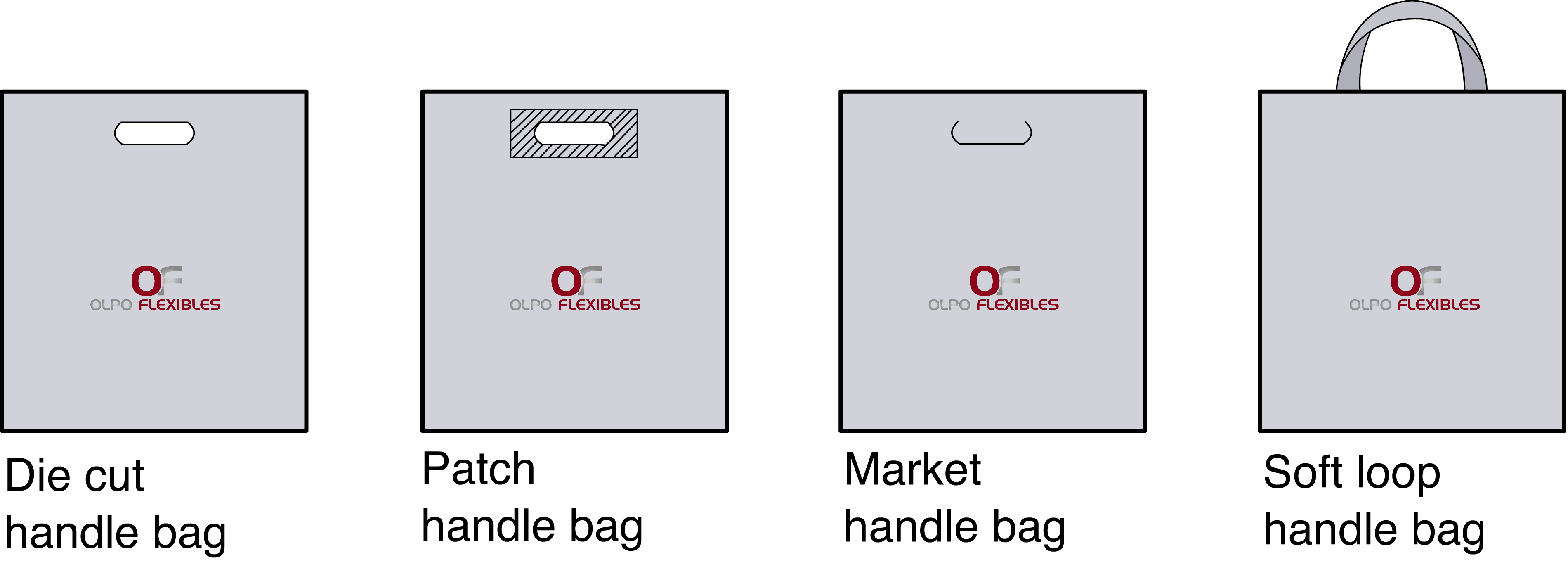

We offer different handles:

- - DKT

- - DKT with enforcement

- - Patch handle

- - Loop handle bag

Handle bags can obtain following options:

- - Bottom gusset

- - Top folding

- - Possible widths – 220mm to 650mm

- - Possible heights – 300mm to 740mm

- - Possible widths for “Loop handle bag” – 250mm to 750mm

- - Possible heights for “Loop handle bag” – 250mm to 630mm

If you have any additional questions, please do not hesitate to contact us.

Labels

Bring your brand or announcements anywhere with personalized bottle labels. Branded bottles make a great first impression and offer a unique opportunity to reach people outside of traditional promotional items. They can be carried anywhere and, with our highly durable materials, they'll withstand smudging and peeling.

Bottle labels can be printed with in to 10 colors graphics using Flexo HD technique. The labels are produced from polyethylene or polypropylene films.

If you have any additional questions, please do not hesitate to contact us.